Rosin Technologies Pneumatic Press: Top 3 Game-Changers

Rosin technologies pneumatic press has become a game-changer in cannabis concentrates. Known for delivering high-quality production, these presses offer an optimized platform that meets the needs of any producer, from small-scale enthusiasts to large commercial operators.

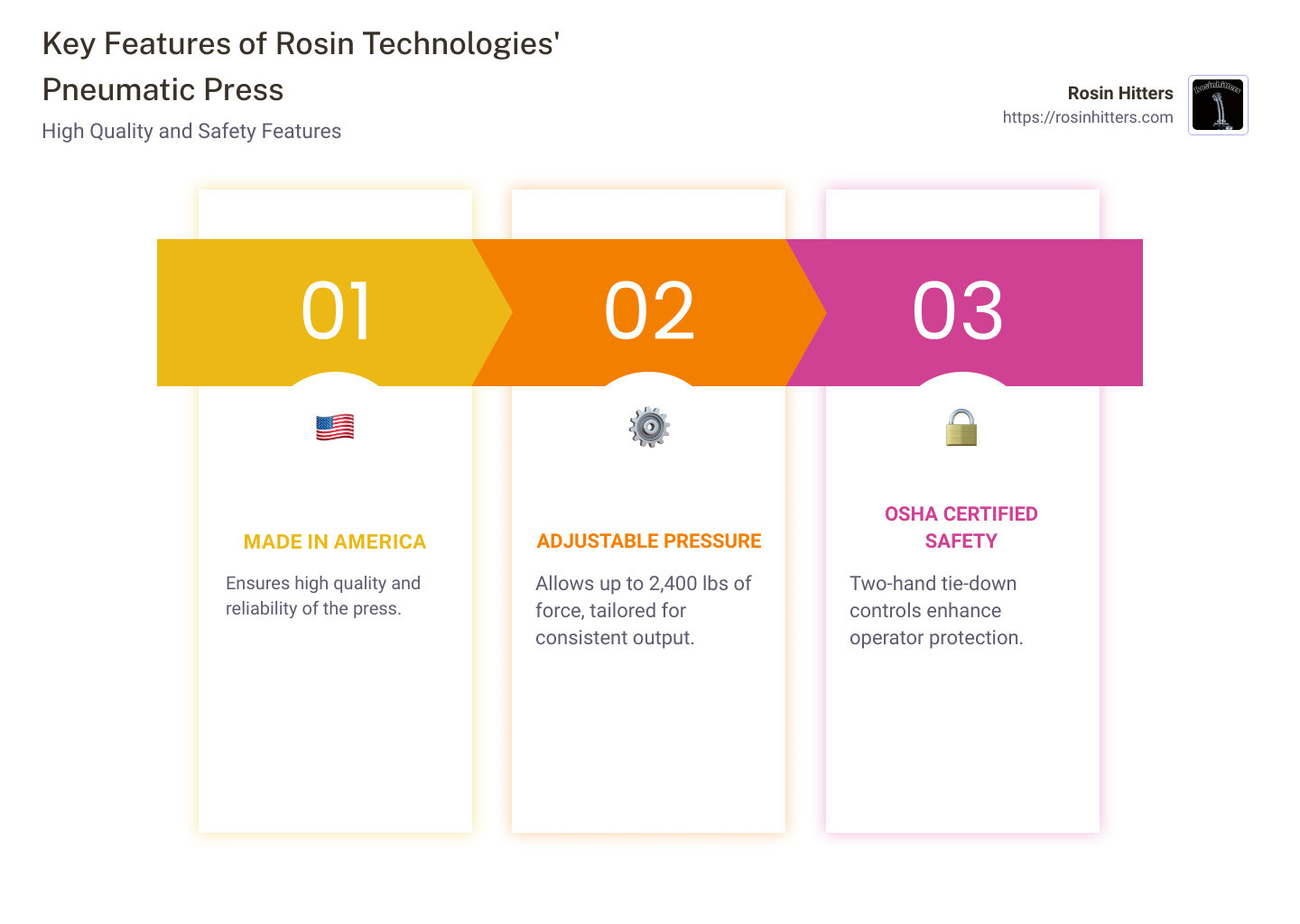

- Made in America: Ensures high quality and reliability.

- Adjustable Pressure: Up to 2,400 lbs of force.

- OSHA Certified Safety: Two-hand tie-down safety controls for operator protection.

Designed for those who seek potent, solventless extracts, the pneumatic press from Rosin Technologies stands out by offering adjustable pressure and digital temperature control. This means each press can be custom to produce consistent, flavorful concentrates that align with personal preferences.

Find why this innovation plays a critical role in crafting superior cannabis products that improve wellness lifestyles, aligning perfectly with the demands of discerning users like Alex.

Understanding Pneumatic Rosin Press Technology

Pneumatic power is at the heart of Rosin Technologies’ presses, providing a powerful yet efficient method for extracting cannabis concentrates. Unlike manual presses, pneumatic presses use air pressure to apply consistent force, making the process smoother and more reliable. This technology allows producers to focus on quality, knowing that their equipment will deliver uniform results every time.

One of the standout features of these presses is their adjustable pressure capability. With the ability to exert up to 2,400 lbs of force, users can fine-tune the pressure to match the specific needs of different materials. This flexibility ensures that whether you’re pressing flower, sift, or bubble hash, you achieve optimal results without compromising on the integrity of the product.

Digital temperature control adds another layer of precision to the process. With a temperature range from room temperature to 300º F, operators can set the exact heat needed for their specific material. This control is crucial because the right temperature can significantly affect the quality and yield of the extract. Lower temperatures often preserve more terpenes, leading to a more flavorful concentrate, while higher temperatures might increase yield but potentially at the cost of flavor.

Together, these features make Rosin Technologies’ pneumatic presses a versatile tool in the arsenal of any concentrate producer. The combination of pneumatic power, adjustable pressure, and digital temperature control allows for a level of customization and efficiency that is hard to match.

This innovative technology ensures that producers can consistently create high-quality, solventless extracts, meeting the expectations of even the most discerning users.

Key Features of Rosin Hitters’ Pneumatic Presses

Rosin Hitters’ pneumatic presses are packed with features that improve both performance and safety, making them ideal for producers seeking high-quality and consistent results.

Dual Stainless Steel Heating Platens

The dual stainless steel heating platens are a standout feature of these presses. Measuring 1.75″ x 2.75″, these platens ensure even heat distribution, which is crucial for achieving a consistent and high-quality extract. The stainless steel construction not only provides durability but also maintains the heat stability necessary for precise processing.

OSHA Certified Safety Controls

Safety is a top priority, and Rosin Hitters has integrated OSHA certified two-hand safety controls into their pneumatic presses. This design requires the operator to engage both hands to activate the press, significantly reducing the risk of accidental injuries. Such safety measures ensure that users can operate the equipment with confidence, knowing that their wellbeing is protected.

Adjustable Downstroke Speed

Another key feature is the adjustable downstroke speed, which offers users control over the pressing process. This adjustability allows for fine-tuning of the press speed, providing an additional layer of customization to match the specific needs of different materials. Whether you’re aiming for a quick press or a more gradual application of pressure, this feature ensures that you can achieve the desired results with ease.

Together, these features make Rosin Hitters’ pneumatic presses a powerhouse of efficiency and safety. The combination of dual stainless steel heating platens, OSHA certified safety controls, and adjustable downstroke speed provides users with the tools they need to produce high-quality concentrates consistently and safely.

Leading seamlessly into the next section, we’ll explore how these features compare across different models of Rosin Hitters’ pneumatic presses.

Comparing Rosin Technologies’ Pneumatic Press Models

Rosin Technologies offers a range of pneumatic presses, each custom to meet specific needs and preferences. Let’s take a closer look at three distinct models: the Thin & Skinny Rosin Press, the Pneumatic PrePress, and the Brick Rosin Press.

Thin & Skinny Rosin Press

The Thin & Skinny Rosin Press is designed for those who prioritize precision and efficiency in small-batch processing. With its compact dual stainless steel heating platens measuring 1.75″ x 2.75″, this press is perfect for handling 3.5-5 grams of flower or 2-8 grams of concentrate. Its pneumatic power ensures consistent pressure, while the adjustable downstroke speed allows for fine-tuning to achieve optimal extraction results. This model’s standout feature is its ability to let rosin escape quickly, preserving the quality of the extract.

Pneumatic PrePress

The Pneumatic PrePress is a crucial accessory for those looking to streamline their pressing process. It prepares flower with up to 2,400 lbs of pressure, creating pucks that fit perfectly into rosin filters. This model’s open workspace design makes it easy for operators to transition from pre-pressing to the main pressing stage. Safety is paramount, with OSHA certified two-hand safety controls ensuring user protection. The Pneumatic PrePress is an excellent choice for those who want to maximize efficiency and safety in their workflow.

Brick Rosin Press

While specific details about the Brick Rosin Press are not provided in the research, it can be inferred that this model is likely designed for larger-scale operations. Built with the same commitment to quality and safety as other Rosin Technologies models, the Brick Rosin Press probably features robust construction and high-pressure capabilities to handle more significant quantities of material. This press would suit producers aiming for high-volume output without compromising on the quality of their extracts.

Each of these models showcases Rosin Technologies’ commitment to innovation and quality in the field of rosin pressing. By offering a variety of options, the company ensures that every producer can find a press that meets their unique requirements. Whether you need precision for small batches or power for larger operations, Rosin Technologies’ pneumatic presses are designed to deliver outstanding results.

Next, we’ll explore the benefits of using pneumatic rosin presses, highlighting how these models contribute to streamlined processing and high force output.

Benefits of Using Pneumatic Rosin Presses

Pneumatic rosin presses offer a range of benefits that make them a preferred choice for producers aiming for efficiency and quality. Let’s dig into the key advantages these presses bring to the table.

Streamlined Processing

With pneumatic power, these presses simplify the extraction process. The adjustable pressure settings allow operators to optimize the force applied, ensuring consistent results with minimal manual effort. This capability is particularly valuable for those handling multiple batches, as it reduces downtime and increases throughput.

Open Workspace

An open workspace is a standout feature of these presses, allowing operators to move freely and handle materials with ease. This design improves workflow efficiency by making it simple to transition between different stages of the pressing process. For example, the Pneumatic PrePress offers a spacious area that facilitates quick and easy puck preparation, which is crucial for maintaining a smooth production line.

High Force Output

Pneumatic presses deliver impressive force outputs, with some models like the Pneumatic PrePress reaching up to 2,400 lbs. This high force capability ensures thorough extraction, maximizing yield while maintaining the quality of the rosin. The ability to apply such pressure consistently is essential for achieving the best possible results, especially when dealing with dense materials.

These benefits illustrate why pneumatic rosin presses are a game-changer in the field of solventless extraction. They combine power, precision, and ease of use to support both small-scale artisans and large-scale producers in their quest for high-quality rosin.

Next, we’ll address some frequently asked questions about pneumatic rosin presses, including ideal temperature ranges and the role of pneumatic power in enhancing pressing efficiency.

Frequently Asked Questions about Pneumatic Rosin Presses

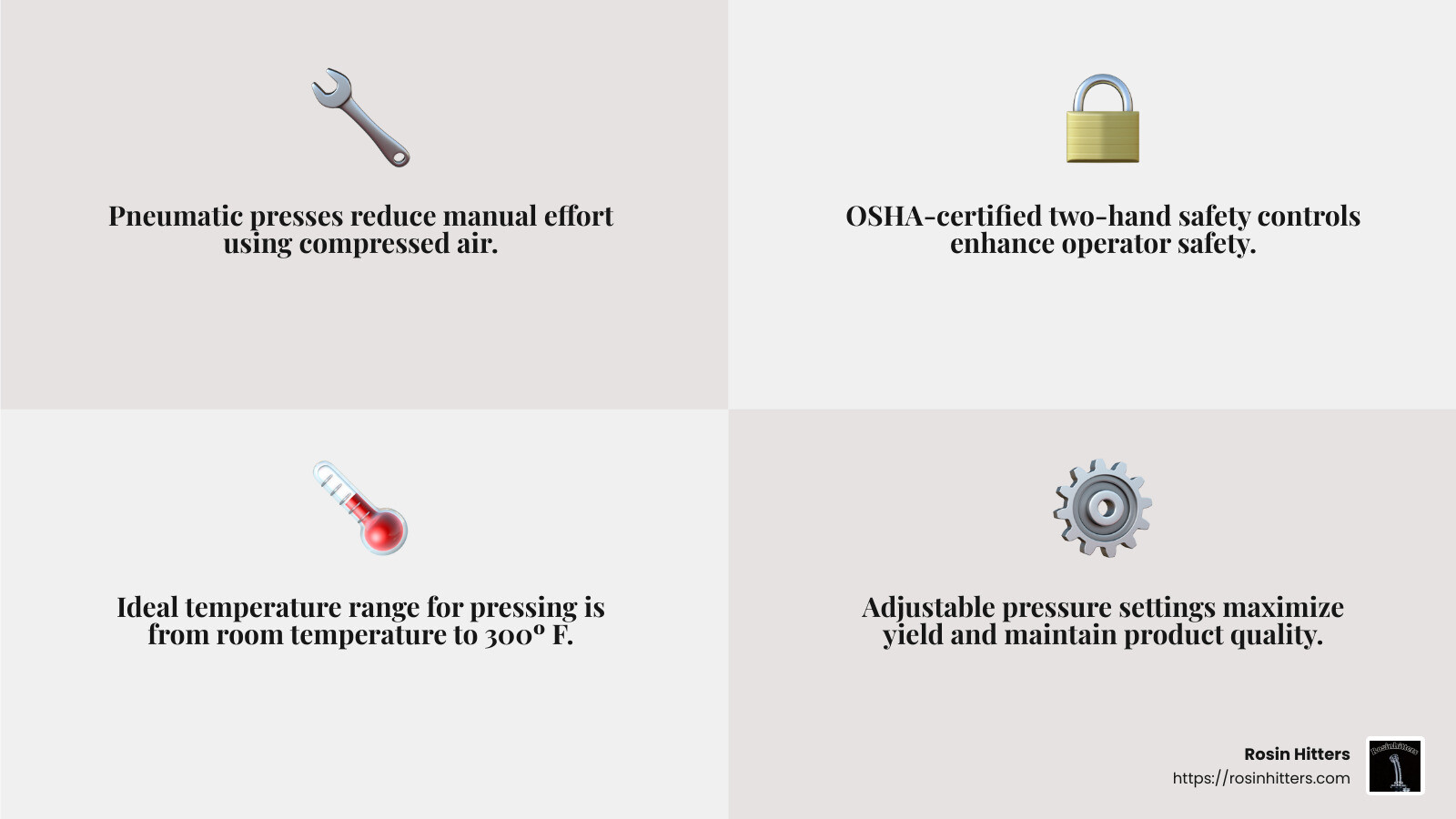

What is the ideal temperature range for pressing?

When using a pneumatic rosin press, maintaining the right temperature is crucial for optimal extraction. The recommended temperature range is from room temperature up to 300º F. This range allows for flexibility depending on the material being pressed and the desired consistency of the rosin. Lower temperatures can preserve more terpenes, resulting in a flavorful concentrate, while higher temperatures can increase yield but may affect flavor.

How does pneumatic power improve pressing efficiency?

Pneumatic power is a game-changer for pressing efficiency. It uses compressed air to generate pressure, which reduces the need for manual force. This mechanism allows for precise pressure control, ensuring consistent results across batches. With adjustable pressure settings, operators can tailor the force to suit different materials, maximizing yield and maintaining quality. This efficiency is particularly beneficial in commercial settings where time and consistency are critical.

What safety features are included in these presses?

Safety is paramount when operating high-pressure equipment like pneumatic rosin presses. These presses are equipped with OSHA certified safety features, including two-hand safety controls. This design ensures that both hands must be engaged to operate the press, reducing the risk of accidental activation. Such safety measures protect operators and promote a safe working environment, making these presses a reliable choice for both small and large-scale operations.

Incorporating these features, pneumatic rosin presses provide a safe, efficient, and effective solution for producing high-quality rosin. Next, we’ll dig into how Rosin Hitters is advancing the field of solventless cannabis concentrates with cutting-edge rosin press technology.

Conclusion

Rosin Hitters is at the forefront of the cannabis industry, offering solventless cannabis concentrates that are both pure and flavorful. Our commitment to quality is evident in the advanced rosin press technology we employ, which ensures that every extract is free from chemical solvents. This dedication to purity allows us to cater to a diverse range of users, from personal enthusiasts to commercial operators.

Our innovative approach centers around the use of pneumatic rosin presses, which streamline the extraction process while maintaining the integrity of the product. By utilizing adjustable pressure and digital temperature control, these presses provide precision and consistency. This technology not only improves the quality of the concentrates but also improves efficiency and safety in production.

At Rosin Hitters, we believe that the future of cannabis concentrates lies in solventless methods, and our cutting-edge technology positions us as leaders in this field. Whether you’re looking for premium rosin or exploring the benefits of live rosin, our products deliver exceptional results every time.

Experience the purity and potency of our solventless concentrates. Explore our live rosin products and find the difference that advanced rosin press technology can make.